Hairpin Motor Stator Coil Froming Technology Solution

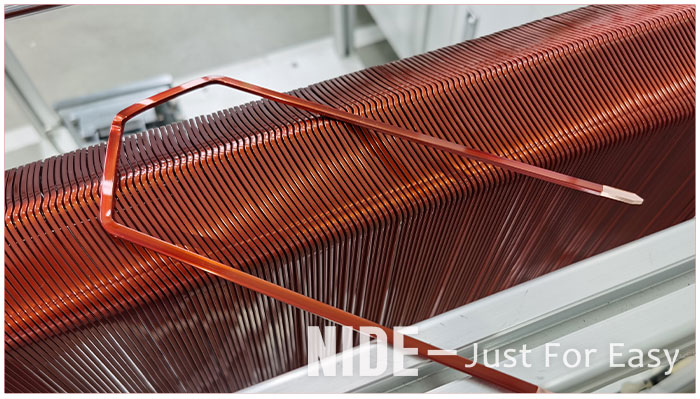

Since the stator copper wire winding of the flat wire motor is a flat thick copper wire, the stator wire package cannot be formed by winding like round copper wire, and must be processed one by one through the forming machine. After the hairpin is formed, the hairpin wires are inserted into the stator core in groups, and finally assembled into the finished motor stator through equipment such as flaring, twisting, welding and varnishing. Key control points of the hairpin forming machine: multi-axis shear control, rewinding and unwinding control, electronic cam, electronic gear, etc.

The main function of the hairpin forming machine is to remove the paint, bend and form the flat copper wire, and finally fold it into a fixed hairpin shape. It is one of the most critical equipment on the entire hairpin motor stator assembly line. Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles.Suitable for EV Car Motor Manufacturing ,New Energy Vechile Motor making, Automobile Drive Motor Stator manufacturing.

Hairpin coil forming technology solution

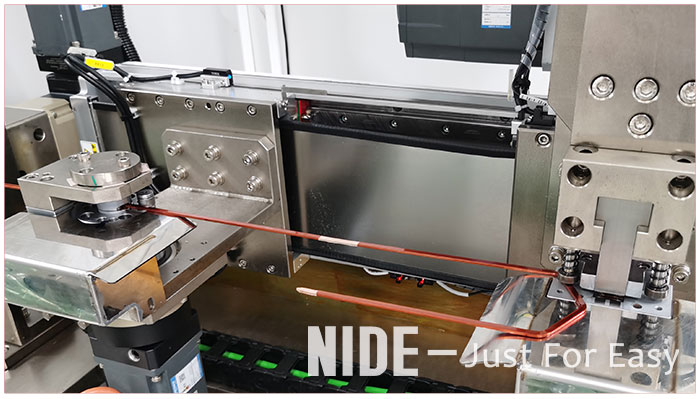

The process of the hairpin forming machine is mainly divided into unwinding, peeling, 2D bending, fixed length cutting and hairpin 3D forming. The unwinding of the flat copper wire is divided into active unwinding and passive unwinding, and a certain tension needs to be guaranteed to straighten the copper wire. There are two types of peeling: mechanical scraper and laser peeling. Fixed-length cutting is to cut the copper wire into fixed lengths. The forming stations are divided into mold stamping and spring machine forming. This application adopts passive unwinding, mechanical scraper peeling and stamping forming.

The forming of different wire lengths requires shutdown switching

The main virtual axis drives all other related axes, and the electronic cam synchronization scheme is used to change the length of the wire feeding within the main virtual axis cycle to switch the hairpin forming of different wire lengths in real time.

Characteristics of hairpin stator wire forming machine

1. Special equipment for forming and processing of hairpin coils of new energy drive motors;

2. The main structure includes: wire feeding mechanism, straightening mechanism, punching and paint removal mechanism, wire release mechanism, cutting mechanism, forming mechanism, waste suction mechanism, wiring mechanism, etc.

Automatic Hairpin Coil froming Process

Ningbo NIDE Tech Co., Ltd, adhering to the customer-centric concept, focuses on the stator, rotor and complete assembly of various motors, and provides customers with one-stop solutions for highly automated, intelligent and flexible production. At present, the products cover the professional manufacture of new energy motor stator and rotor, hairpin motor, automatic aluminum casting rotor line, brushless motor/ BLDC motor, universal motor, wheel hub motor, etc., which are used in new energy vehicles, household appliances, industrial motors, water pump motors, servo motors, etc. Provide customers with a variety of new energy motor manufacturing solutions, including round wire motor manufacturing solutions, flat wire motor manufacturing solutions, hairpin flat wire technology solutions, flat wire hairpin stator forming machines, etc.

中文版

中文版 English

English