Manufacturing process of brushless motor for washing machine

The Automatic BLDC motor production assembly line is suitable for washing machines. The motor Drive system is based on interior permanent magnet brushless motor technology, delivers a higher speed spin to wash speed ratio for multiple wash modes. The BLDC motor has very long life, high efficiency and quiet operation. The efficient brushless dc motor reduces energy consumption by 40% in comparison to traditional induction motors. The BLDC motor supports the constantly innovating washing machine design requirements, for the high-performance washing results and energy savings.

This innovative drive motor technology delivers the wider speed range and supports multi-wash modes for improved washing performance. We can supply the full automatic washing machine brushless DC motor manufacturing assembly line. The main production process of this automatic motor assembly line is as follows:

1. Automatic BLDC rotor assembly line

Auto shaft inserting machine. This machine can automatic press-fitting the rotor core and shaft of the motor. The performance is stable and accurate, the pressing depth is uniform, and the precision is high.

Auto ball bearing inserting machine. The machine can automatically pressing the Bearings on both ends of the rotor.

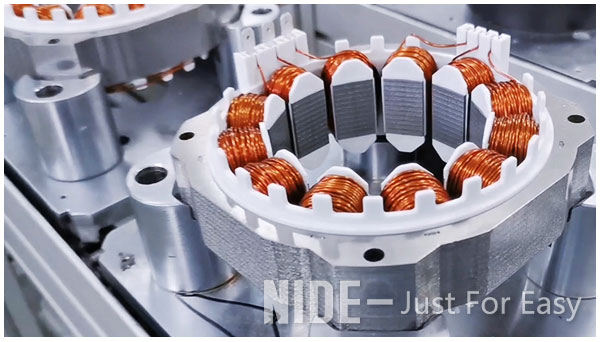

2. Automatic BLDC stator assembly line

Auto Insulation paper inserting machine. The machine can automatically complete paper cutting, folding and inserting.

Auto End insulator pressing machine. This machine automatically presses the insulation board end plate on both ends of the rotor.

Auto Needle winding machine. The motor winding machine is suitable for the winding of the stator of the servo motor, the BLDC stator winder adopts the needle inner winding design, single-station operation, and can simultaneously wind three slots in the winding, and the whole coil winding process is automated and efficient, safe, multi-strand winding at the same time, the coil winding speed can reach up to 800 rpm, and different types of brushless stators can be wound according to customer requirements. This BLDC stator needle winder has self-diagnosis function.

Auto stator wire end termination machine. The stator termination machine automatically organizes the wire end. The wire end length can be adjusted.

Auto Terminal Inserting and Stator Testing Machine. The machine can automatically feeding, positioning, pick-up, pressing, test the stator performance.

3. Automatic BLDC motor assembly line

This automatic motor assembly line is suitable for assemble varies type BLDC motor, such as BLDC washing machine motor stator, compressor motor, vacuum cleaner motor, power tool motor, etc.We could accomplish tailored and innovative solutions to meet all quality and production requirements.

Click here to view the brushless motor manufacturing line

About NIDE

The NIDE Group can supply professional motor production mechanical, motor manufacturing solution and electric motor components. Our products are suitable for automotive applications, domestic equipment, power tool, aeronautical applications, industrial mechanicals and medical devices, etc.

中文版

中文版 English

English