release time:2024/07/29

Compared with round wire motors, flat wire motors have high slot filling rate, high power density, good NVH performance, good heat dissipation, and are easy to realize automated production. Its disadvantages are large AC loss, high process difficulty, and large equipment investment.

Among them, X-PIN motor can reduce the size of welding end wire package by 8-12mm.

But at the same time, there are the following process problems: head twisting control, head cutting, welding clamping, paint burning and other problems.

Design input stator slot type, copper wire gauge, connection diagram

3D feature recognition

Parameter assignment

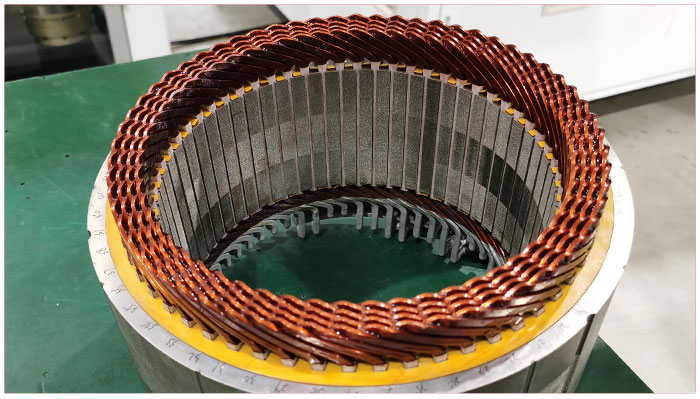

Hairpin wire 3D modeling

Winding connection

Line shape optimization

Appearance design

Molding mold, determine the stator envelope size as integrated layout input

Thermal field, NVH simulation model input

Core feeding

Paper insertion

Wire forming, wire insertion, copper wire transfer

Copper wire pressing

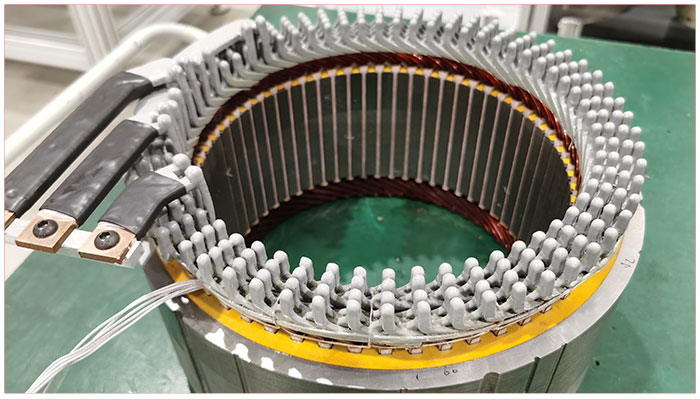

Flaring

Twist head

Cut flat tool installation

Cut flat

Connecting wire welding

Welding inspection

Repair welding

Remove cut flat tool installation

Welding

Repair welding

Remove tool installation

Thermistor installation

Electrical performance testing

Coating on line

Heating

Coating

Coating curing

Pre-paint insulation

Paint dripping

Paint dripping curing

Cooling off line

Appearance inspection

Three-wire copper busbar welding

Electrical performance testing

Laser marking

Dimensional appearance inspection

Cleaning

Finished product off line

Mechanical depainting: stamping, grinding, scraping

Process characteristics: fast cycle, clean depainting, poor flexibility, damage to copper wire, regular mold replacement.

Laser depainting:

Process characteristics: small damage to copper wire, good consistency, good flexibility, high equipment cost, attention should be paid to depainting residue and black edge problems.

Structural design and process thinking

Splitting and pulling forming: suitable for motors with large aspect ratio and few winding layers.

CNC forming: large equipment investment, high flexibility, convenient linear compensation, slow cycle.

Mold forming: stable linear size, simple equipment, fast cycle, easy to damage wire, poor flexibility.

Mixed forming: 2DCNC+3D mold

Manual wire insertion: manually insert the formed copper wire directly into the stator core in the prescribed order. Suitable for low requirements for line accuracy, low equipment investment, slow beat, uneven U-shaped ends, easy to insert the wrong wire, easy to damage the wire and paper.

Automatic wire insertion: Generally, the equipment automatically inserts the formed copper wire into the transfer wire cup, and then the equipment grabs the winding as a whole and inserts it into the stator core. Stable quality and fast beat. High requirements for line accuracy. High equipment investment and high process difficulty.

Semi-automatic wire insertion: Manually insert the formed copper wire into the transfer wire cup, and then the equipment grabs the winding as a whole and inserts it into the stator core.

Between manual and automatic, the process difficulty is moderate and widely used.

Classification: single-layer twisting, multi-layer twisting

Requirements: No biting or top wire. No explosion or cracking of the insulation paper. The position of the solder joints is accurate and neat. The size of the wire package meets the requirements.

Laser welding: stable quality and fast cycle. Small heat-affected zone. High requirements for joint position. Welding is prone to spatter. Large equipment investment.

Requirements: The welds are uniform, full and free of defects. The paint is intact and there is no spatter. The wire package size meets the requirements. The welds meet the requirements for pull-out force and penetration depth.

Ningbo Nide Mechanical Equipment Co., Ltd. focuses on providing customers with highly automated, information-based, intelligent, and flexible overall motor manufacturing solutions, focusing on stators, rotors and complete machine assembly lines for various motors. We have provided flat wire motor manufacturing solutions and round wire motor manufacturing solutions to many customers around the world, which are used in new energy vehicles, industry, home appliances, etc. Especially for round wire motor manufacturing lines, we have rich design experience and a professional technical team to provide customers with a series of automated motor manufacturing equipment such as motor stator manufacturing lines, rotor manufacturing lines, and motor assembly lines to meet customers' customized needs for motor manufacturing.

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.