release time:2024/07/17

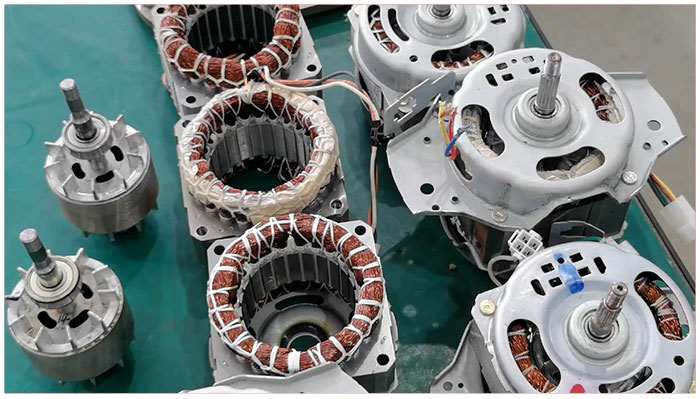

Currently, washing machine motors mainly include induction motors, series motors, three-phase variable frequency motors, DC brushless motors and other types. Induction motors are generally used in double-barrel semi-automatic and fully automatic washing machines; series motors, three-phase variable frequency motors, and DD DC brushless motors are generally used in drum washing machines.

The current structure of the motor is related to factors such as the purpose of the motor, speed, protection type, ventilation and cooling method, and installation form. Although different types of motors have different structures, they are all composed of three major parts, namely the fixed part, the rotating part and the auxiliary part. The auxiliary parts are bearings, brush devices, coolers, etc.

The following mainly introduces the manufacturing structure of the washing machine induction motor

The fixed part of the washing machine induction motor is mainly composed of stator frame, frame, stator core, stator winding, end cover and support and fixing parts.

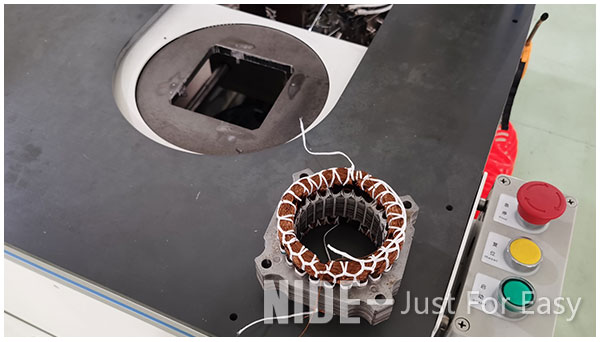

The stator structure of the entire washing machine motor is not very complicated, but its manufacturing process is very delicate.

The main steps are:

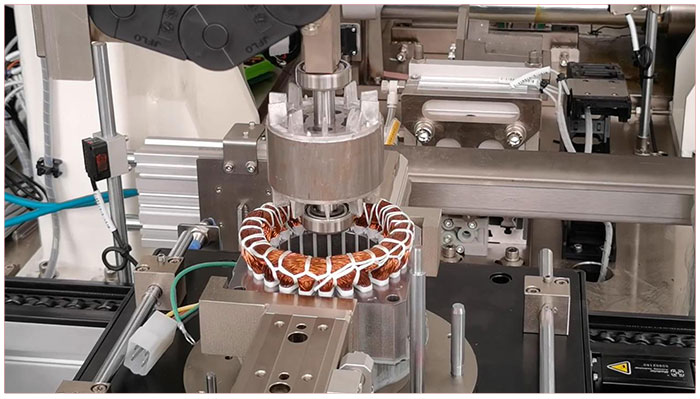

Paper insertion, winding, shaping, wire binding, performance testing, dipping insulating paint, etc.

Main steps: rotor aluminum casting, fine machining, shaft pressing, retaining spring pressing, bearing pressing

Ningbo Nide Mechanical Equipment Co., Ltd., was established in 2010, committing to provide customers with highly automated, intelligent, and flexible motor manufacturing solutions, and focusing on the production line of stator, rotor and final assembly of various motors.

We provide customers with a variety of electric motor manufacturing solutions, including BLDC motor manufacturing assembly machines, induction motor manufacturing line, universale motor manufacturing sloution, etc., which are mainly used in automotive motors, Industrial motor, Pump motor, Home appliances motors, etc. We can also customize complete brushless motor manufacturing solutions according to customer needs. If you need, please feel free to contact us.

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.