Fully Automatic Three-Phase Motor Stator Production Line with Remote App Control

Model number:ND-DZXSJ

Introduction:This fully automatic three-phase motor stator production line with mobile app control is engineered to boost productivity, precision, and automation in motor stator manufacturing. Designed for applications such as washing machine motors, table fan motors, and small industrial motors, this line integrates advanced machines for paper inserting, coil winding, lacing, and forming—delivering high-efficiency stator production with minimal human intervention.

- Specification

Fully Automatic Three-Phase Motor Stator Production Line with

Remote App Control

The Fully Automatic Three-Phase Motor Stator Production Line offers a cutting-edge solution for

modern motor manufacturers seeking automation, efficiency, and scalability. The integration of mobile

app-based remote control enables real-time monitoring and operational adjustments from anywhere,

enhancing flexibility and ease of use.

This automated line is especially suitable for high-volume washing machine stator assembly, table fan

stators, BLDC stators, and other three-phase motor stator applications.

Key Features & Advantages

Fully Automated Workflow: Includes insulation paper inserting, coil winding and inserting, lacing,

and forming—streamlining production and reducing labor dependency.

Mobile App Control: Enables remote monitoring, fault diagnosis, and real-time parameter settings

via smartphone.

High Production Efficiency: Optimized for mass production with fast cycle times and minimal downtime.

Precision Manufacturing: Servo-driven systems ensure coil accuracy, clean insertion, and consistent quality.

Customizable Operation: Parameters adjustable per stator model through a user-friendly HMI interface.

Production Process Flow

Slot Paper Inserting Machine

Inserts insulation paper into stator slots with high precision.

Coil Winding and Inserting Machine

Performs automated coil winding and insertion, supporting parallel wires and multiple pole configurations.

Stator Coil Lacing Machine

Secures the windings using Mylar wedges with programmable spacing.

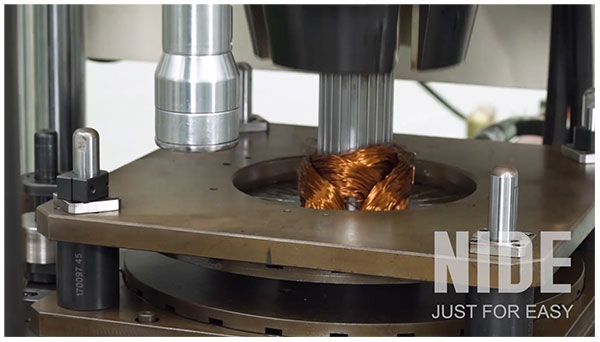

Stator Coil Forming Machine

Shapes the stator to exact specifications without damaging the winding.

Technical Specifications

Flyer Swing Diameter: 240mm

Stack Length: ≤90mm

Stator Outer Diameter: ≤150mm

Winding Speed: ≤2200 RPM

Number of Wire Jumps: 2-4 sections

Wire Diameter: 0.18-1.2mm

Parallel Winding Wire Number: ≤2

Air Pressure Requirement: 0.5 ~ 0.6 MPa

Power Consumption: 14kW

Machine Weight: 4000kg

Operating Temperature: -10°C to 60°C

Machine Dimensions: 2700mm (L) × 2300mm (W) × 2200mm (H) (including wire barrel)

Machine Components in Detail

1. Automatic Stator Coil Winding and Inserting Machine

Three winding stations, each independently controlled.

AC servo motor for precise indexing, wire cutting, and paper feeding.

Cam divider for rapid and accurate coil insertion.

Parallel winding without damaging enameled wire.

XY-axis movement for wire hooking and cutting.

2. Automatic Coil Lacing Machine

Servo-driven wedge paper feeding for consistent lacing.

Adjustable wedge length and slot spacing.

Built with hardened steel for durability and accuracy.

3. Automatic Coil Forming Machine

High-precision shaping with damage-free insertion.

Pre-deceleration and speed control features.

Real-time monitoring and automatic wire break detection

Applications

This production line is ideal for:

Washing Machine Motor Stators

Table Fan Motor Stators

HVAC Compressor Stators

BLDC Motor Stators

Industrial Pump Motor Stators

Why Choose NIDE?

As a ISO-Certified Motor Manufacturing Solutions Provider, NIDE delivers:

Turnkey Projects: From stator lines to full motor assembly systems

Global Support: 24/7 technical consulting & spare parts logistics

Component Ecosystem: Commutators, bearings, shafts, and insulation materials

Watch YouTube Demo Video

About NIDE - Your Reliable Partner in Motor Manufacturing Equipment

NIDE Group specializes in the R&D and manufacturing of motor production machinery. We offer a full range

of solutions including standalone machines, fully automatic production lines for armature and stator, and

complete motor assembly lines. With over a decade of experience, we support clients with high-efficiency

equipment and tailored automation solutions for various motor types.

Our product portfolio also includes motor components such as commutators, ball bearings, carbon brushes,

insulation paper, shafts, magnets, cooling fans, and motor covers. In addition, NIDE provides technical consulting,

project design, and turnkey services to help clients optimize their motor manufacturing processes.

Machines Application

NIDE machines are widely used in the production of various motor types, including:

AC motors / DC motors / BLDC motors / universal motors / induction motors

Single-phase and three-phase motors

Common application fields:

Household appliances: washing machines, air conditioners, vacuum cleaners, electric mixers,

electric shavers, hair dryers, electric toothbrushes

Industrial equipment: pumps, compressors, power tools, fans, coolers

Automotive: electric vehicles, hub motors, alternators

NIDE helps manufacturers build efficient, automated motor production lines for both high-volume

and customized projects. More information please check our New Website: www.nidegroup.com.

Global Service & Support

NIDE offers global installation support, training, and after-sales services. Our engineering team ensures

smooth machine integration and continuous production performance. Contact us for technical consultation

for guidance on equipment selection.

Contact Us

marketing8@nide-group.com (Head of Electric Machinery and Equipment)

emarketing@nide-group.com (Head of Motor Parts)

SNS

中文版

中文版 English

English