Balance car motor external armature wedge inserting machine

Model number:DCCP2-200B

Introduction:The external rotor wedge inserting machine is used for wheel hub motor armature insulation wedge inserting.

- Specification

(1) Application:

The external rotor wedge inserting machine is used for wheel hub motor outer armature insulation wedge inserting process ,and the wedge inserter is sutiable for balance car motor, balance scooter motor, wheel hub motor.

(2) Main Feature

Indexing automatic by servo system, wedge feeding and inserting pneumatically. The working frequency is infinitely variable speeds. The slot number and wedge inserting slot can be set in the HMI. After wedge run out , machine will auto alarm.

(3) Technical parameter:

Product name:

Wheel hub motor rotor wedge inserting machine

motor external rotor OD:

150~200mm

motor external rotor height:

18~35mm

Insulation wedge thickness:

3.5-6mm

Pithc time:

30s/1pc

Power supply:

220V/ 50/60Hz 0.6Kw

Weight:

350Kg

Dimension:

1650*450*1500mm

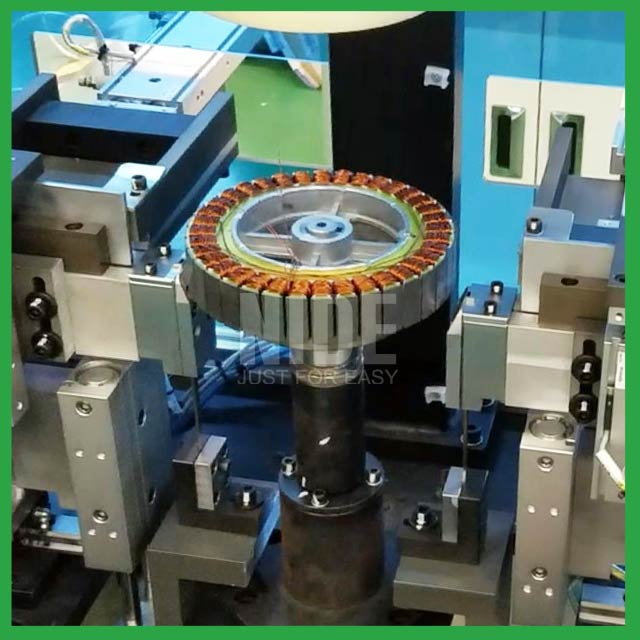

(4) Picture show:

Balance car wheel motor external armature

Balance scooter wheel motor external armature wedge inserting process

Balance scooter wheel motor external armature wedge machine

Balance car motor armature insulation wedge insertion process youtube video

Besides paper inserting machine, we also supply different types of insulation materials for stator or armatures, such as insulation paper and wedge with different class degree. DMD Class B/F, DM Class B/F, Polyester film Class E, Red Vulcanized Fiber Class A, NH& NHN, etc

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English