60T Four working stations Aluminum rotor die casting machine

Model number:ND-60T

Introduction:This rotor die casting machine is safety, healthy, power saving and labor cost saving.

- Specification

Machine feature of rotor die casting machine

Automatic get aluminum melt liquid, automatic loading and unloading the rotor.

Rotor loading: automatic pneumatic circularly pick up.

Get aluminum melting liquid: servo motor control the mechanical arm, control the liquid volume through human-machine interface.

Automatic cut the waste material, automatic recycle the cut wasted material and convey it to the furnace by the conveyor.

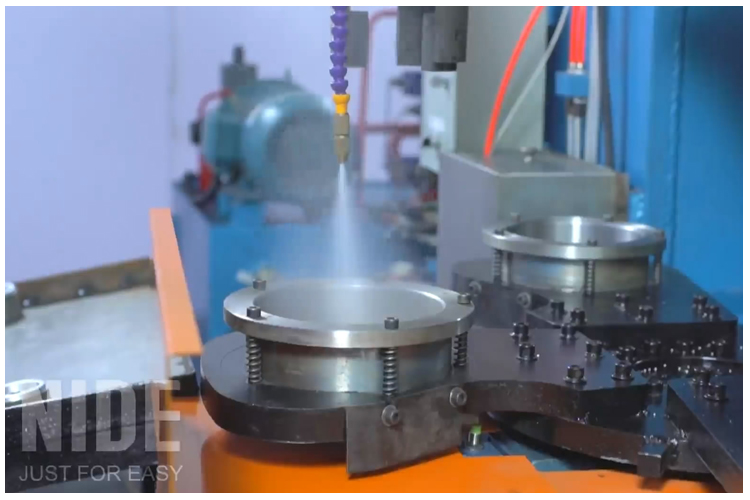

Automatic feed mold releasing agent, the feeding time and times can be set.

There is water cooling channel, helpful for reducing the mold temperature effectively.

Setting on touch screen: forward and backward speed, stroke, swing angle of the mechanical arm, loading speed,etc.

Machine will alarm and stop working if out of material.

Failure will be automatic displayed and machine will alarm.

One person can take care of more than one machine.

Comparing with the conventional die casting machine, Our automatic rotor die casting machine has following features.

a. labor cost saving, only one operator required, the aluminum scrap automatic recycle.

b. safe, it is very easy for operator to run the machine, operator only need to press "start" button, no need to handling the heavy tooling which might occur body injury, and the machine has aluminum anti spatter design to prevent the aluminum liquid from spraying and cause injury.

c. Healthy, our machine doesn't need asbestine cup to keep the temperature and demould

d. Power saving, and tooling cost is much less and fast tooling changeover.

etc

一、Specification No. Item Unit 60Tspecification 1、Main cylinder: 1 main cylinder mold lock force KN 400 2 main cylinder mold lock travel mm 200 2、Injecting cylinder: 1 Injecting cylinder travel mm 150 2 Injecting cylinder injecting force KN 200 3 Injecting force(Min-Max) KN 70-200 4 capacity L 10 5 aluminum depot OD(Max) mm 65-75 6 punching head OD(Max) mm 65-75 7 aluminum depot capacity(Max) kg 0.5 8 Injection punching head travel distance mm 50 9 cycle time s 10 10 Rotor OD mm Max 75 11 Rotor stack height mm Max 70 3、Motor and pump: 1 Pump motor power KW 7.5 2 Divider motor powder KW 0.2 3 Oil pump (plunger pump) L 40Y 4、Machine dimension: 1 Main frame(L*W*G) mm 1700*1600*

2200

2 assembly of oil tank and electric appliance(L*W*G) mm 1500*1000

*900

3 turntable OD mm 860 5、Cooling pump specification: 1 Submersible pump power KW 1.1 2 Submersible pump rate of flow M3/H 3.5 3 Submersible pump water pressure MPa 0.4 Remark: the max pressure of this machine is 25Mpa / Submersible pump power 220/380V Optional Apart from the rotor die casting machine, we supply full range machines for stator and rotor manufacturing, such as stator coil winding machine, coil inserting machine, rotor assembly line, rotor turning machine, etc.

About Motor armature manufacturing

Motor armature / rotor manufacturing production assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English