- Specification

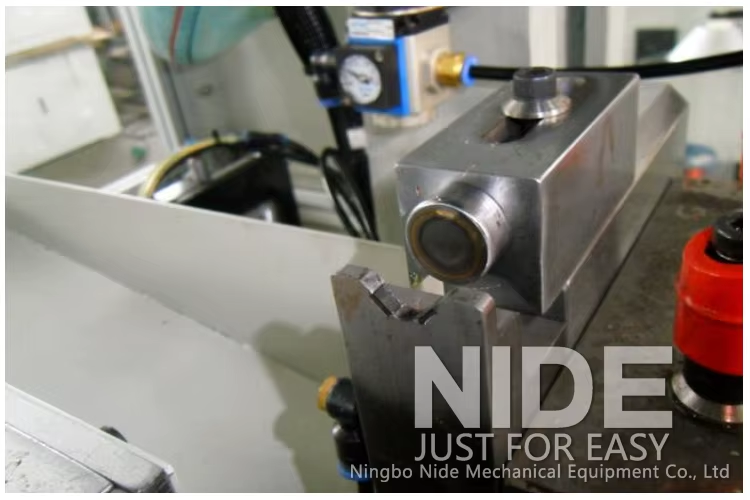

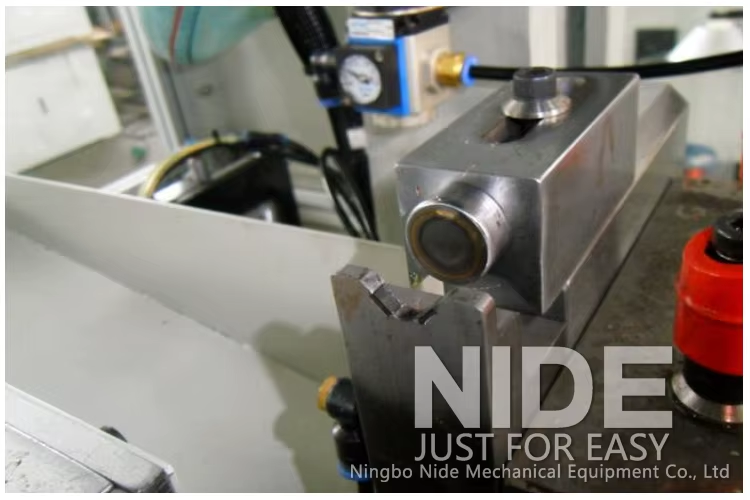

This commutator turnning machine is suitable for turning various type of armatures. Servo motor takes use of universal coupling to drive flat belt; Rotor rotary was done by pressure friction between flat belt and rotor round OD. Rotor shaft do high speed coaxial rotary on arc diamond V-shape holder. Cross feed and longitudinal feed was carried out by servo motor and ball screw. This action was done continuously to finish high precision turning. All actions are controlled by PLC.

Technical Parameter

1. Process precision: Inter-segment roundness < 1.5um, surface roughness < 0.4um

2. Speed adjustment range

The speed adjustment range is from 0Hz to 100Hz. Meanwhile, user can set any belt speed on touch screen.

3. Feeding value

It could be set up randomly among 1um-0.1um. Normally, 1st feeding value is bigger than 2nd one, 2nd one is bigger than 3rd one and last one could be set up by factory on its experience.

4. Turning times

The maximum turning time of the X spindle direction is 4 times, while so is the Z spindle direction. User could set the turning times for each rotor according to their own needs.

5. Control mode

There are two control modes, single action and automatic action. Commission can be done under the on condition of single action.

6. Operation: Setting up and parameters revise even password modification and commission can all be done in touch screen.

7. Compressed air: Air source pressure 0.5MPa~0.7Mpa(5Kgf/cm2~7Kgf/cm2)

8. Motor: AC servo motor 750W OMRON

9. Power supply: AC380V+/-5% 50Hz/60Hz

10. Weight and dimension: Around 1100KG 1300mm x 900mm x1570mm

About Motor armature manufacturing

Motor armature / rotor manufacturing production assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English