Products

Model :ND-DZX9

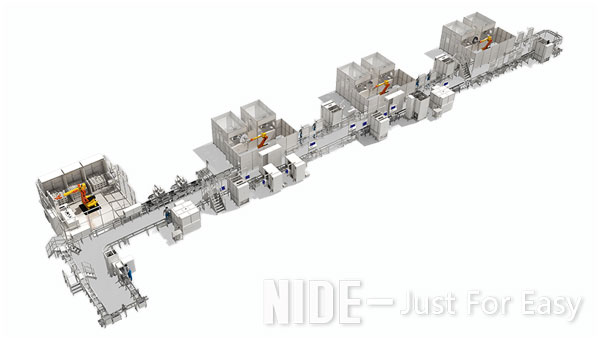

Brief Introduction : The New Energy Motor Stator Production Line integrates slot insulation paper inserting, laser marking, coil winding and inserting, pre-forming, phase paper inserting, Star spot welding, middle forming, double-sided lacing, final forming, terminal welding, stator testing, NG rework, stator unloading functions.

Automatic EV New Energy Motor Stator Production Line

This stator production line is mainly suitable for the production of Electric Car EV motor stators; the whole line is highly automatic and adopts advanced design schemes.

The New Energy Motor Stator Production Line integrates slot insulation paper inserting, laser marking, coil winding and inserting, pre-forming, phase paper inserting, Star spot welding, middle forming, double-sided lacing, final forming, terminal welding, stator testing, NG rework, stator unloading functions.

This EV motor production line is a new stator production line, which is intellectualized, automatic and informational in one. It features time changing time for whole line within 2 hours.

Application

This stator production assembly line is suitable for New Energy Vehicle Motor Manufacturing.

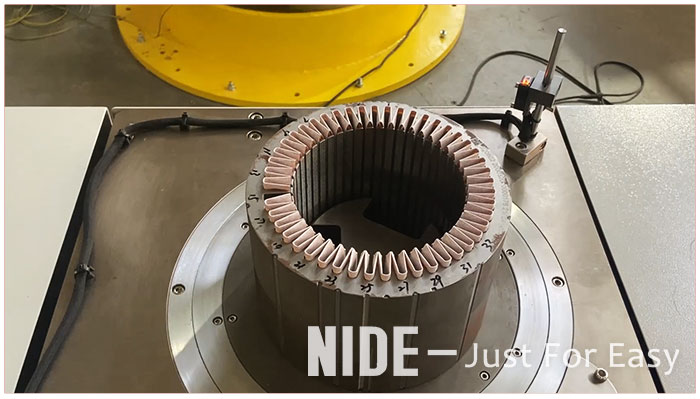

Basic Specification:

| -Stator O.D.: | Φ150mm-Φ250mm |

| -Stator I.D.: | Φ90mm-Φ190mm |

| -Stator Stack Length: | 60mm-160mm |

| -Slot Number: | 36-72 |

| -Slot opening width: | ≥1.6mm |

Production Process

Manually load the stator core to paper inserting machine via cantilever

Manually load the stator coil to pallet after inserting

Print QR code on stator terminal end/arc side

Insert wire coil into stator core

Manually sort wires from third phase

Manually sort wires from third phase and install tubes

Pre-forming for terminal ends

Manually insert the phase insulation paper

Manually sort wires

Insert copper tube and weld with star-point

Automatic middle-forming

Automatic double-sides lacing

Automatic final-forming

Automatic slot end paper expanding

Manually sort and cut wires, install terminals, cut pre-lacing Nylon type; Automatic weld terminals

Manually stator eye testing and then loose pallet clamping block

Test for stator voltage, phase sequence, resistance, and etc.

Stator core delivery

Front stator double-speed flow Chain

Back stator double-speed flow Chain

Technical Proposal

Cycle time: ≤170 sec/pc

Tooling changing time for whole line within 2 hours (needs workers within 10 persons)

Equipped with MES to realize production process traceability and electric boards for whole production lines and equipped working stations.

100% for reliability of testing system and online inspection rate for key parameter

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.