Products

Model :ND-HMPX-2

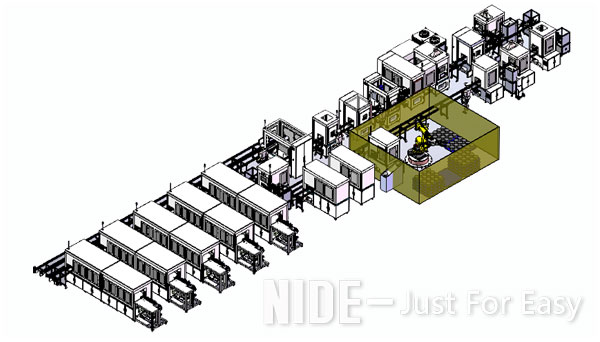

Brief Introduction : The Hairpin Stator Production Line for Flat Wire EV Motors is a fully automated and intelligent solution for manufacturing hairpin stators used in new energy vehicle (NEV) drive motors. Designed to support the production of 2 to 10-layer flat wire stators, this advanced line features a high degree of automation, MES integration, digital traceability, and modular flexibility. With a cycle time of 100 seconds and a compact footprint, it significantly boosts production efficiency, product quality, and factory intelligence—helping EV motor manufacturers stay competitive in the fast-growing electric mobility industry.

This fully automated production line is tailored for the manufacturing of hairpin stators

in flat wire drive motors used in electric vehicles (EVs) and new energy vehicles (NEVs).

It supports multi-layer stator production (2–10 layers) and meets the demands of high-speed,

high-efficiency, and high-precision motor manufacturing.

High Automation & Intelligence: Complete line automation including paper insertion, coil

forming, insertion, end twisting, welding, testing, and coating processes.

MES Integration: Enables production data traceability, quality monitoring, and remote control.

Flexible Configuration: Adaptable for different motor stator specifications and production volumes.

Compact Footprint: Efficient use of factory space, total layout area only 30m x 12m.

High Yield & Consistency: Cycle time of 100 seconds per stator ensures stable high-volume output.

Production Cycle Time (C/T): 100 seconds per stator

Production Capacity: Suitable for 2 to 10-layer hairpin stators

Line Dimensions: 30 meters × 12 meters

System: Fully integrated with MES (Manufacturing Execution System)

Insulation Paper Inserting

Hairpin Forming

Hairpin Coil Inserting

End Twisting (Twist Forming)

Flat Cutting of Hairpin Ends

Hairpin Laser Welding

Busbar Welding

Coil Electrical Testing

Varnish Coating / Trickling

Comprehensive Performance Testing

B-type Paper Inserting Machine

Hi-pot & End Expanding Machine for Insulation Paper

Hairpin Forming Machine

Hairpin Inserting Machine

End Expanding Machine

Hairpin End Twisting Machine

Perpendicularity Correction and Measurement Machine

Hairpin Flat Cutting Machine

Hairpin Laser Welding Station

Coil Testing Equipment

Vacuum Trickling Machine

Busbar Welding Machine

Laser Marking Machine

Final Stator Testing Machine (with PDIV testing)

About NIDE - Your Reliable Partner in Motor Manufacturing Equipment

NIDE Group specializes in the R&D and manufacturing of motor production machinery. We offer a full range

of solutions including standalone machines, fully automatic production lines for armature and stator, and

complete motor assembly lines. With over a decade of experience, we support clients with high-efficiency

equipment and tailored automation solutions for various motor types.

Our product portfolio also includes motor components such as commutators, ball bearings, carbon brushes,

insulation paper, shafts, magnets, cooling fans, and motor covers. In addition, NIDE provides technical consulting,

project design, and turnkey services to help clients optimize their motor manufacturing processes.

NIDE machines are widely used in the production of various motor types, including:

AC motors / DC motors / BLDC motors / universal motors / induction motors

Single-phase and three-phase motors

Common application fields:

Household appliances: washing machines, air conditioners, vacuum cleaners, electric mixers,

electric shavers, hair dryers, electric toothbrushes

Industrial equipment: pumps, compressors, power tools, fans, coolers

Automotive: electric vehicles, hub motors, alternators

NIDE helps manufacturers build efficient, automated motor production lines for both high-volume

and customized projects. More information please check our New Website: www.nidegroup.com.

Global Service & Support

NIDE offers global installation support, training, and after-sales services. Our engineering team ensures

smooth machine integration and continuous production performance. Contact us for technical consultation

for guidance on equipment selection.

Contact Us

marketing8@nide-group.com (Head of Electric Machinery and Equipment)

emarketing@nide-group.com (Head of Motor Parts)

SNS

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.