Products

Model :ND-DZX6

Brief Introduction : The Automated Motor Stator Manufacturing Line Solution is a scalable, intelligent production system designed for the efficient and high-precision manufacturing of stators used in various types of motors, including those for household appliances, water pumps, fans, power tools, medical equipment, and new energy vehicles. This solution integrates fully automated processes such as paper inserting, coil winding, coil embedding, forming, and lacing, significantly reducing labor dependency while improving production consistency, flexibility, and throughput. Ideal for motor manufacturers aiming to optimize cost-efficiency, production automation, and quality control in a highly competitive market.

The Motor Stator Manufacturing Line Solution is designed to serve small and medium-sized

electric motor production, with applications across home appliances, HVAC systems, water pumps,

medical devices, fans, power tools, and electric vehicles (EVs).

This solution adopts advanced automated and intelligent manufacturing technology, delivering

high-volume output while addressing labor shortages and diverse stator design requirements.

Labor-saving & Cost-efficient:

Reduces operator dependency, lowers labor costs, and optimizes floor utilization with efficient

layout and workflow.

High Automation & Consistency:

Automates critical stator processes including slot insulation, coil winding, coil inserting, forming,

and lacing—ensuring high process stability and reduced defect rates.

Modular & Flexible Setup:

Machines are programmable, with easy changeovers and HMI interface for parameter settings.

Each station works independently and can be customized for various motor types.

Scalable & Industry-Proven:

Applicable to a wide range of motor types such as BLDC motors, induction motors, synchronous

motors, stepper motors, three-phase motors, and series motors.

Stator Slot Paper Inserting

Coil Winding (primary & auxiliary phase)

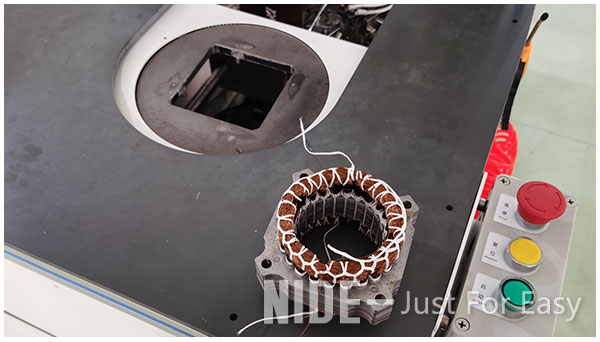

Wire Embedding / Coil Inserting

Pre-forming & Final Shaping

Lead Wire Crimping

Lacing (slot/interval/fancy options)

Appearance Inspection & Electrical Testing

Packing

1. Stator Paper Inserting Machine

Cycle time: ≤1s/slot (excluding loading/unloading)

First-pass yield: ≥99%, post-rework: ≥99.9%

Supports a wide range of stator sizes and paper forms.

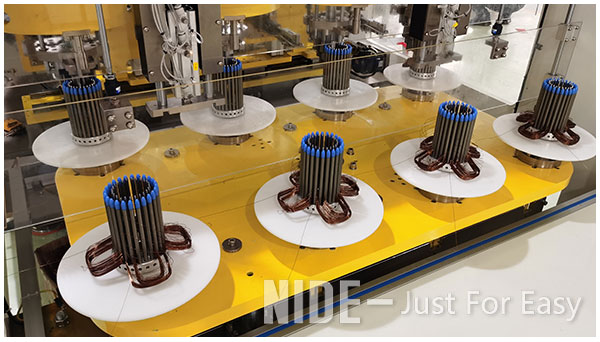

2. Automatic Coil Winding Machine

4 winding heads, 8 working stations

Supports 2/4/6-pole stators

Features auto skip, auto cutting, auto indexing

High slot fill ratio; compatible with small slot openings

Suitable for various wire diameters and coil shapes

3. Stator Coil Lacing Machine

PLC-controlled with multiple lacing modes: slot, interval, fancy

Fast tooling change

Available in single-station, double-station, and horizontal models

Cycle Time: Optimized for high-speed production

MES Compatible: Ready for smart factory integration

Operator Role: Only required for loading/unloading and visual inspections

Quality Assurance: Final stator test performed via integrated testing unit

This production line is widely applicable in industries such as:

Home Appliance Motor Manufacturing

HVAC and Pump Industry

Electric Vehicle Motor Production

Medical and Industrial Equipment

Motor Stator manufacturing production line solution youtube video

About NIDE - Your Reliable Partner in Motor Manufacturing Equipment

NIDE Group specializes in the R&D and manufacturing of motor production machinery. We offer a full range

of solutions including standalone machines, fully automatic production lines for armature and stator, and

complete motor assembly lines. With over a decade of experience, we support clients with high-efficiency

equipment and tailored automation solutions for various motor types.

Our product portfolio also includes motor components such as commutators, ball bearings, carbon brushes,

insulation paper, shafts, magnets, cooling fans, and motor covers. In addition, NIDE provides technical consulting,

project design, and turnkey services to help clients optimize their motor manufacturing processes.

NIDE machines are widely used in the production of various motor types, including:

AC motors / DC motors / BLDC motors / universal motors / induction motors

Single-phase and three-phase motors

Common application fields:

Household appliances: washing machines, air conditioners, vacuum cleaners, electric mixers,

electric shavers, hair dryers, electric toothbrushes

Industrial equipment: pumps, compressors, power tools, fans, coolers

Automotive: electric vehicles, hub motors, alternators

NIDE helps manufacturers build efficient, automated motor production lines for both high-volume

and customized projects. More information please check our New Website: www.nidegroup.com.

Global Service & Support

NIDE offers global installation support, training, and after-sales services. Our engineering team ensures

smooth machine integration and continuous production performance. Contact us for technical consultation

for guidance on equipment selection.

Contact Us

marketing8@nide-group.com (Head of Electric Machinery and Equipment)

emarketing@nide-group.com (Head of Motor Parts)

SNS

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.