Products

Model :ND-QYD-0.5T

Brief Introduction : This end plate pressing machine is suitable for BLDC brushless motor stator insulation board / end plate pressing

I.The insulation board pressing Machine structure and function:

1.Machine consists of main machine, pneumatic system, electric control system, force measuring system;

2. The main cylinder and the top of the cylinder equipped with a pressure switch . And the main cylinder compression stroke adjustable, to avoid over-pressure caused by insulation board rupture;

3.Pneumatic system consists three port five through reversing valve, filter regulation valve, pressure regulation valve, silencer and necessary pneumatic attachments;

4.Electric control system consists of miniature circuit breaker, indicator, time relay, middle relay, switch button and necessary electric attachments;Electrical components (such as sensors, pressure switches, etc.) with plug-type;

5.safety device from the light curtain, the protection of a high degree of 500mm, three semi-enclosed protective cover,

6.Double palm start buttons, operation panel is at the front side of the machine;it is very easy to operate

7.Adapts emergency button, once it has emergency situation, press down this button, machine will stop working immediately, it enhance the safety and reliability;

8.Material conveyor and machine height can be adjusted;In the material conveyor with a cylinder to prevent NG parts into the next process;

9.Add 2 insulation panels to the left and right of the machine.

10.Manual loading, automatic unloading, can be connected to automatic lines.

11.Piston cylinder pressing down stroke is adjustable, helpful for protecting the end plate from bearing too much pressure;

12.There is guiding device, during pressing, there is no axis direction rotation;

13.There is filter pressure reducing valve, pressure is adjustable.

II.The main technical information:

Working table of the main machine: 285×320(mm)

closing height:300mm

working stroke:150mm

Working pressure: 5KN (0.5T)/ 0.4Mpa

maximum. Open the height: 200mm

Work schedule: 150mm

Table size: 650 * 700mm

Throat depth: 175mm

The distance between the workbench and the floor: 780 mm

Stator out of the cylinder stroke: 100mm, working pressure: 10Kg

Cabinet size: 500 * 200 * 600mm

Rack and cover: 40 * 40mm aluminum.

Table and the ground distance: 1000mm (with brake wheel)

Material Conveyor Length: 700mm (with 1 set of cylinder)

Machine color: aluminium alloy color or customized

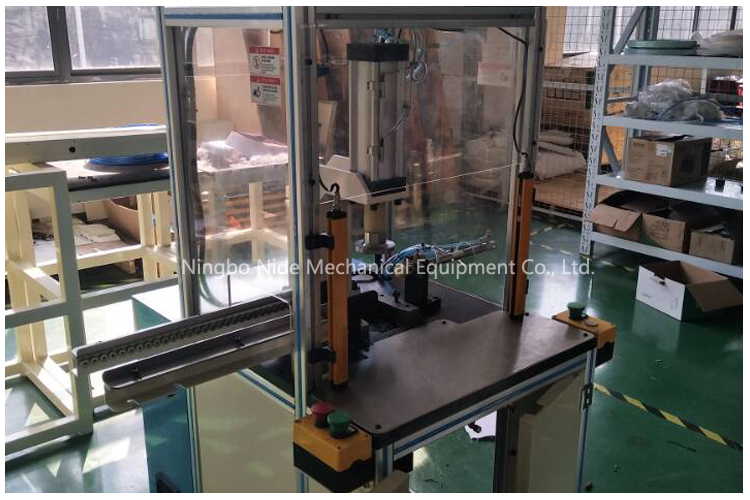

III.Picture show

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.