Products

Model :ND-DZX1

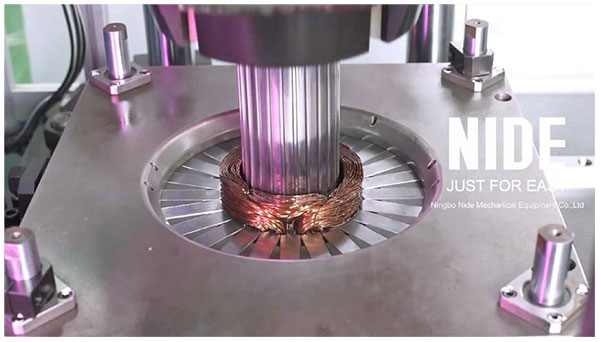

Brief Introduction : This fully automated stator assembly line is engineered to reduce labor dependency, enhance production efficiency, and maintain high output with minimal workforce. It integrates key processes such as insulation paper insertion, coil winding and inserting, wire binding, shaping, and final testing, connected by robotic arms and intelligent control systems to ensure seamless workflow and high precision. Ideal for large-scale motor manufacturing operations.

The Automated Stator Assembly Line for Motor Manufacturing is designed to minimize labor costs

and increase production efficiency in motor stator manufacturing. By integrating modular machines and

robotic transfer systems, this solution ensures a streamlined and precise assembly process that enhances

productivity and product consistency.

Modular Line Design: The production line consists of interconnected workstations and standalone

machines linked by robotic arms and mechanical handlers to automate part transfer and process transition.

Independent Control System: Each station features standalone PLC control for flexible, independent

operation and seamless coordination.

Central Line Control: Equipped with an intelligent line control system that manages stop gates, lifts,

and positioning units for stator handling.

Automated Paper Insertion Station: With auto-loading, unloading, and positioning, the slot insulation

process is fully automated.

Yaskawa Robotic Arm Integration: Ensures precise and stable transfer of stators between the paper

insertion and coil winding/inserting stations.

Custom Mechanical Grippers: Used for transfer between shaping and wire binding stations, ensuring

alignment and process continuity.

Dual-Function Binding Machine: Automatically completes both tying and knotting tasks in a single cycle.

Automated Testing System: Conducts resistance, hi-pot, and insulation resistance testing, and classifies

stators into qualified and unqualified groups for downstream processes.

Included Equipment and Specifications

Stator Stack Height: 20–90mm

Outer Diameter: Max 135mm

Inner Diameter: 20–90mm

Folded Edge Height: 2–7mm

Paper Thickness: 0.188–0.35mm

Cycle Time: ≈0.5s/slot

Power: 0.75kW

Dimensions: 1200×650×1100mm

Weight: ≈200kg

Outer Diameter: ≤150mm

Inner Diameter: ≤110mm

Stack Height: 30–120mm

Number of Parallel Wires: 3

Wire Diameter: 0.18–1.2mm

Insertion Method: Chain / Concentric

Cycle Time: ≤40s/piece

Power: 15kW

Dimensions: 2000×1300×2300mm

Weight: ≈4000kg

Outer Diameter: 40–160mm

Inner Diameter: ≤100mm

Stack Height: 30–160mm

Coil Height: ≤65mm

Cycle Time: ≤14s/piece (24 slots)

Power: 6kW

Dimensions: 2000×1100×1900mm

Weight: ≈1500kg

Inner Diameter: 30–110mm

Outer Diameter: Max 160mm

Stack Height: 20–200mm

Coil Height: ≤45mm

Oil Cylinder Displacement: 20L/min

Power: 3.75kW

Dimensions: 1300×1000×2400mm

Weight: ≈500kg

This stator assembly line is suitable for a wide range of electric motor stator manufacturing scenarios,

including but not limited to:

Three-phase induction motors

Washing machine motors

Fan motors

BLDC motors

HVAC and pump motor stators

The Motor stator automatic manufacturing production line working video

About NIDE - Your Reliable Partner in Motor Manufacturing Equipment

NIDE Group specializes in the R&D and manufacturing of motor production machinery. We offer a full range

of solutions including standalone machines, fully automatic production lines for armature and stator, and

complete motor assembly lines. With over a decade of experience, we support clients with high-efficiency

equipment and tailored automation solutions for various motor types.

Our product portfolio also includes motor components such as commutators, ball bearings, carbon brushes,

insulation paper, shafts, magnets, cooling fans, and motor covers. In addition, NIDE provides technical consulting,

project design, and turnkey services to help clients optimize their motor manufacturing processes.

NIDE machines are widely used in the production of various motor types, including:

AC motors / DC motors / BLDC motors / universal motors / induction motors

Single-phase and three-phase motors

Common application fields:

Household appliances: washing machines, air conditioners, vacuum cleaners, electric mixers,

electric shavers, hair dryers, electric toothbrushes

Industrial equipment: pumps, compressors, power tools, fans, coolers

Automotive: electric vehicles, hub motors, alternators

NIDE helps manufacturers build efficient, automated motor production lines for both high-volume

and customized projects. More information please check our New Website: www.nidegroup.com.

Global Service & Support

NIDE offers global installation support, training, and after-sales services. Our engineering team ensures

smooth machine integration and continuous production performance. Contact us for technical consultation

for guidance on equipment selection.

Contact Us

marketing8@nide-group.com (Head of Electric Machinery and Equipment)

emarketing@nide-group.com (Head of Motor Parts)

SNS

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.