release time:2025/03/21

Different generator motors are used based on power demands:

Brushless Alternator Motors: Low maintenance and highly efficient.

12-Lead Motors: Provide adaptable voltage configurations for various applications.

Industrial-Grade Alternator Motors: Designed for high-output and long-term operation.

When selecting a motor for a generator system, consider:

Power and Voltage Requirements: Ensure compatibility with your generator setup.

Load Capacity: The ability to handle fluctuating energy demands.

Energy Efficiency Ratings: Reduce operational costs and improve performance.

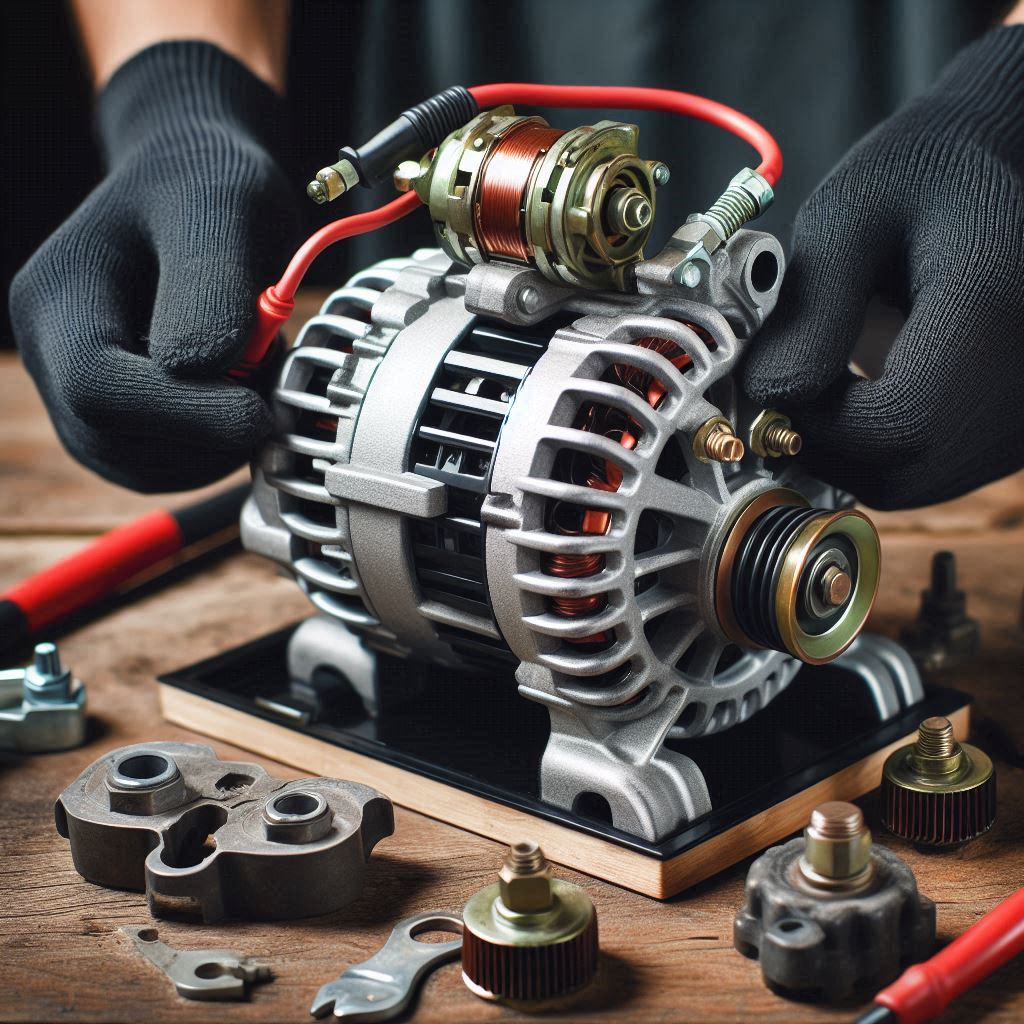

To extend its lifespan and efficiency, follow these maintenance best practices:

Routine Inspections: Check for overheating, wiring issues, and general wear.

Cooling System Maintenance: Prevent excessive heat buildup.

Lubrication of Bearings: Reduce friction and extend motor life.

Regular Load Testing: Ensure the motor operates under real-world conditions.

Voltage and Frequency Monitoring: Maintain a stable electrical output.

Proper upkeep of an alternator-driven motor ensures it delivers optimal power efficiency

in various industrial and backup power applications. Adding a voltage regulator can further

stabilize output, enhancing system reliability.

By selecting and maintaining the right generator motor, businesses and individuals can improve

energy efficiency and ensure uninterrupted electrical supply.

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.