release time:2025/03/07

Models: ND-LAW-5B2 / ND-LAW-5B2B

NID's ND-LAW series features a dual-mode system that adapts to various wire diameters, ensuring stability

in armature coil production.

Feature Magnetic Hysteresis Mode Electric Tension Control Mode

Wire Size 0.16mm – 0.55mm 0.30mm – 0.85mm

Tension Accuracy ±5% ±3%

Best For Power tool motors Automotive wiper motors

Real-World Case Study:

A top global home appliance manufacturer integrated the ND-LAW-5B2 into their electric motor armature production

for washing machines. The machine smoothly transitioned between 0.35mm and 0.50mm wire sizes, reducing defects

from 8.7% to 0.9% (2023 customer acceptance report).

Why Choose It?

✔ Automatic wire diameter detection (±0.01mm accuracy)

✔ One-click mode switching via an HMI screen

✔ Automatic break detection & memory function

This innovation simplifies the winding process, ensuring seamless transitions between different wire specifications

without manual recalibration.

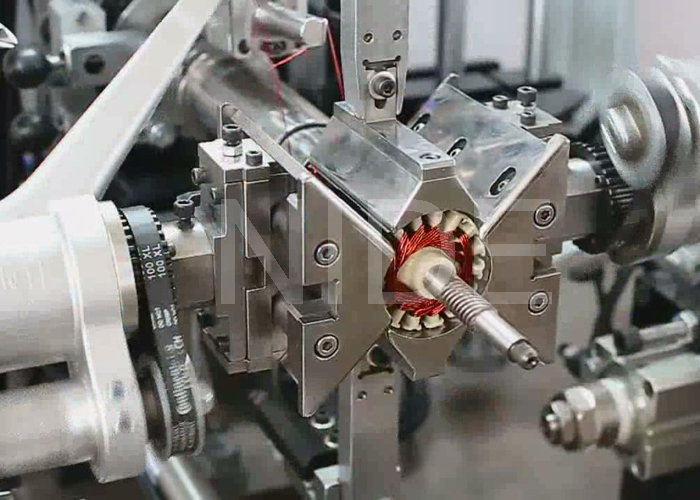

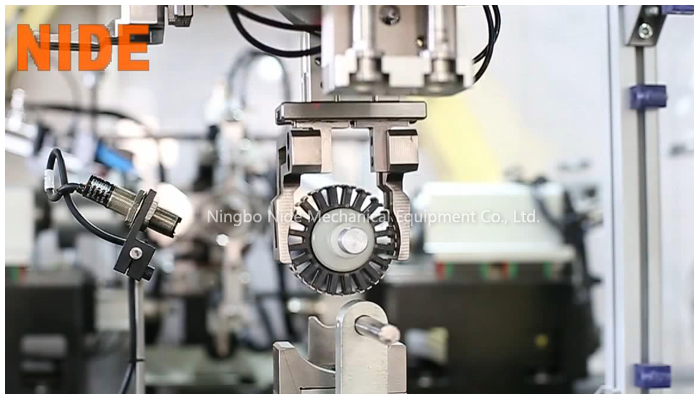

Model: ND-R2W01B

This model is designed for high-speed motor starter armature production, particularly for BLDC outer rotors.

Key Benefits:

✅ Dual-station system: While one rotor is winding, the next is clamped, doubling productivity.

✅ Auto wire clamping: Pneumatic clamps respond in under 0.3 seconds.

✅ Self-diagnostic system: Monitors 32 operational parameters in real time.

Productivity Boost:

Feature Traditional Single-Station ND-R2W01B Dual-Station

Hourly Output 85 units 150 units

Model Change Time 22 minutes 6 minutes

Operators Needed 2 people 1 person

Best Applications:

High-speed drone motor winding (2000rpm speed)

Small-batch smart home motor production

This machine ensures precise field windings placement and enhances the efficiency of coil winding machines used

in starter motor manufacturing.

Features & Performance:

Model Max Speed Accuracy Best For

ND-LAW-5B2 3000rpm ±0.15° Mid-size home appliance motors

ND-R2W01B 2000rpm ±0.08° Precision drone motors

Technological Advancements:

Mitsubishi Servo System: Dual 1.5KW motors ensure stable power output.

Closed-Loop Feedback Mechanism: A 17-bit absolute encoder continuously monitors position and speed.

Thermal Deformation Compensation: Auto-calibration every 15 minutes prevents overheating issues.

Third-Party Test Results:

Speed fluctuation<0.5% during an 8-hour operation

Vibration value<2.5μm at 3000rpm

These advancements create a winding process that delivers high-speed precision while ensuring every armature

coil interacts with the magnetic field optimally.

Requirement Recommended Model Key Features

Large wire sizes (0.5mm+) ND-LAW-5B2B Electric control, supports up to 60mm armature diameter

High-mix production ND-R2W01B Dual-station, 700rpm rated speed

Quick model changes ND-LAW-5B2 Stores 100 process settings, RFID recognition

Selecting the right motor winding machine ensures:

✔ Faster production with rotating part stability

✔ Precision field windings placement

✔ Seamless adaptability to electric motor armature variations

A great armature starter motor machine is more than just a tool—it’s the key to higher efficiency, lower defect rates,

and seamless automation. Nide's advanced coil winding machines help manufacturers enhance performance while

maintaining precision.

Explore Nide's industry-leading armature winding machines today!

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.