release time:2024/05/22

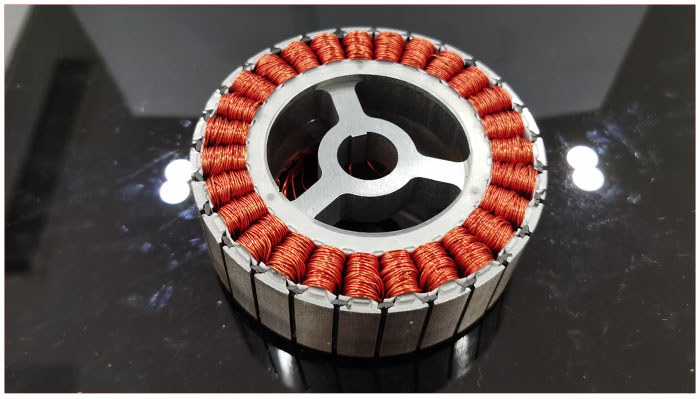

The brushless motor stator winding process can be done manually or with equipment. Both can complete the winding work. Manual winding can satisfy small batches. If large quantities are required, a specialized winding machine is required. So what are the advantages of automatic winding machine equipment compared to manual winding machines?

1. The cable arrangement is compact and precise. Different winding requirements can be realized according to the stator parameters. Precision cable arrangement can be achieved without messing up one wire, and the product consistency is better.

2. Non-standard customization is possible. According to the parameters of the stator, ordinary products use standard equipment, and customized products can use non-standard equipment to meet various diversified needs.

3. It can realize automatic winding, arranging, tapping, transposition, clipping and other processes. It can stop and start at any 360 degrees, with strong flexibility and high stability.

4. You can choose the number of workstations. You can choose equipment with different workstations according to the stator product and your own needs. Generally, single-station, double-station, four-station, and six-station equipment are commonly used. There are many stations. The higher the efficiency, the higher the output, but the price is relatively higher.

5. After a professional debugging process, ensure that the winding is correct and complete, and the salt water leakage value meets the requirements.

6. It has a wide range of applications and products that meet the scope, whether it is inner winding or outer winding, or special-shaped chutes, have corresponding equipment; the clamps are independent modules and can be replaced at any time; the program can be called and adjusted, and there are many types of adjustment.

In short, compared to manual winding, brushless motor stator automatic winding machines have higher efficiency and quality requirements, higher machine stability, and better product consistency.

This winding method is often used for motor stators with outward notches, such as new energy vehicle motors, balancing car motors, model aircraft motors, drone motors, traversing machine motors, scooter motors, and fans. Stators, twist car motors, cooling fan stators, rotary transformers, plant protection machines, various externally wound stators, etc. After each parameter is set, the flying fork is rotated at high speed to drive the copper wire winding, and the protective plate plays an auxiliary role. The copper wire is stuck into the slot, and the die head is moved forward and backward to arrange the wire in an orderly manner, so that each The groove arrangement is precise.

This winding method is often used in motor stators with inward-facing slots, such as power tool motors, washing machine motors, water pump motors, stepper motors, vacuum cleaner motors, gates, winches, etc. After the parameters are set, the tungsten steel wire nozzle moves together with the wire. Through the up and down and forward and backward movement of the guide pin, precise wire arrangement and winding work is achieved.

The above are the two common winding methods for brushless motor winding machines. Master the basic principles of these winding methods and ensure the reasonable design of the stator winding, so that the wire can be wound better and more precisely. Both winding methods have their own advantages, their own applicable ranges and universal models, and they can also be customized. In terms of price, the outer winding method will be relatively cheaper, while the inner winding method will be more expensive. Customers can choose winding machine equipment at different stations according to their required output.

Ningbo Nide Mechanical Equipment Co., Ltd., was established in 2010, committing to provide customers with highly automated, intelligent, and flexible motor manufacturing solutions, and focusing on the production line of stator, rotor and final assembly of various motors.

We have provided customers with a variety of brushless winding solutions, including flying fork winding machines and needle winding machines, which are mainly used in wheel hub motors, new energy motors, automotive motors, balancing car motors, and drone motors. Vacuum cleaner motors, power tool motors, washing machine motors, stepper motors, water pump motors, etc. We can also customize complete brushless motor manufacturing solutions according to customer needs, please feel free to contact us if you need it.

Copyright © Ningbo Nide Mechanical Equipment Co., Ltd.